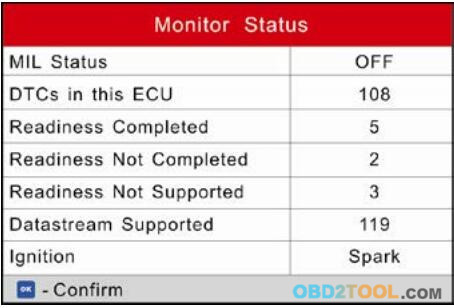

Select [Diagnose] in Main Menu and press [OK], the screen will display Monitor Status interface as following figure

1 OBDII/EOBD Diagnosing

1 OBDII/EOBD Diagnosing

This

option presents a quick way to check for DTCs, isolate the cause of the

illuminated Malfunction Indicator Lamp (MIL), check monitor status

prior to emissions certification testing, verify repairs, and perform a

number of other services that are emission-related. In Figure 5-1, press

[OK] to enter system, the screen of

CRP129 Premium will automatically jump to figure

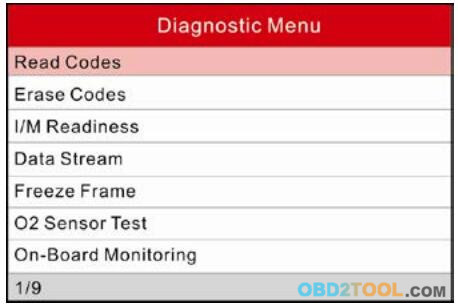

Press [OK], a screen similar to Figure as follow will appear:

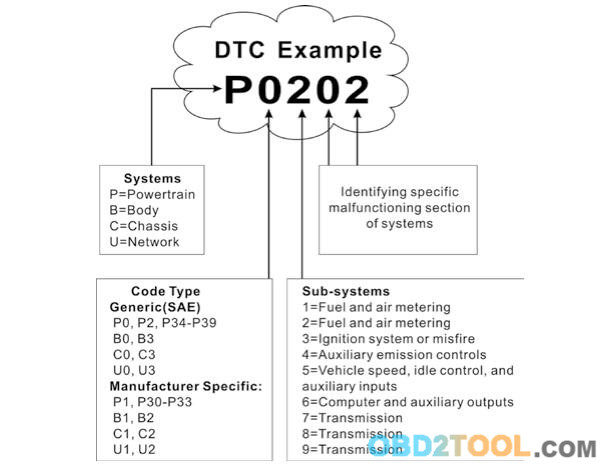

It mainly includes the following functions: 1. Read Codes

It mainly includes the following functions: 1. Read Codes This option is used to identify which section of the emission control system has malfunctioned.

2. Erase Codes

After reading the retrieved codes from the vehicle and certain repairs

have been carried out, you can use this function to erase the codes from

the vehicle. Before performing this function, please be sure the

vehicle’s ignition key is in the ON position with the engine off.

Notes: a. Before performing this function, make sure to retrieve and record the trouble codes.

b. After clearing, you should retrieve trouble codes once more or turn

ignition on and retrieve codes again. If there are still some trouble

codes in the system,please troubleshoot the code using a factory

diagnosis guide, then clear the code and recheck.

3. I/M Readiness

I/M refers to Inspection and Maintenance that is legislated by the

Government to meet federal clean-air standards. I/M Readiness indicates

whether or not the various emissions-related systems on the vehicle are

operating properly and are ready for Inspection and Maintenance testing.

The

purpose of the I/M Readiness Monitor Status is to indicate which of the

vehicle’s Monitors have run and completed their diagnosis and

testing(as described in Chapter 2.5), and which ones have not yet run

and completed testing and diagnosis of their designated sections of the

vehicle’s emissions system.

The I/M Readiness Monitor Status

function also can be used (after repair of a fault has been performed)

to confirm that the repair has been performed correctly, and/or to check

for Monitor Run Status.

4. Data Stream This option retrieves and displays live data and parameters from the vehicle’s ECU.

5. View Freeze Frame When an emission-related fault occurs, certain vehicle conditions are recorded by the on-board computer. This

OBD2 Code Reader Scanner

is referred to as freeze frame data. Freeze Data is a snapshot of the

operating conditions at the time of an emission-related fault.

Note: If DTCs were erased, Freeze Data may not be stored in vehicle memory depending on vehicle.

6. O2 sensor test

The results of O2 sensor test are not live values but instead the

results of the ECU’s last O2 sensor test. For live O2 sensor readings,

refer to any of the live sensor screens such as Graph Screen.

Not

all test values are applicable to all vehicles. Therefore, the list

generated will vary depending on vehicle. In addition, not all vehicles

support the Oxygen Sensors screen.

7. On-board monitor test This function can be utilized to read the results of on-board diagnostic monitoring tests for specific components/systems.

8. EVAP System Test The EVAP test function lets you initiate a leak test for the vehicle’s EVAP system. The

LAUNCH CRP129 Premium Scanner

does not perform the leak test, but signals to vehicle’s on-board

computer to initiate the test. Before using the system test function,

refer to the vehicle’s service repair manual to determine the procedures

necessary to stop the test.

9. Vehicle Info

This option displays the vehicle information, such as VIN (Vehicle

identification Number), CID (Calibration ID) and CVN (Calibration

Verification Number).

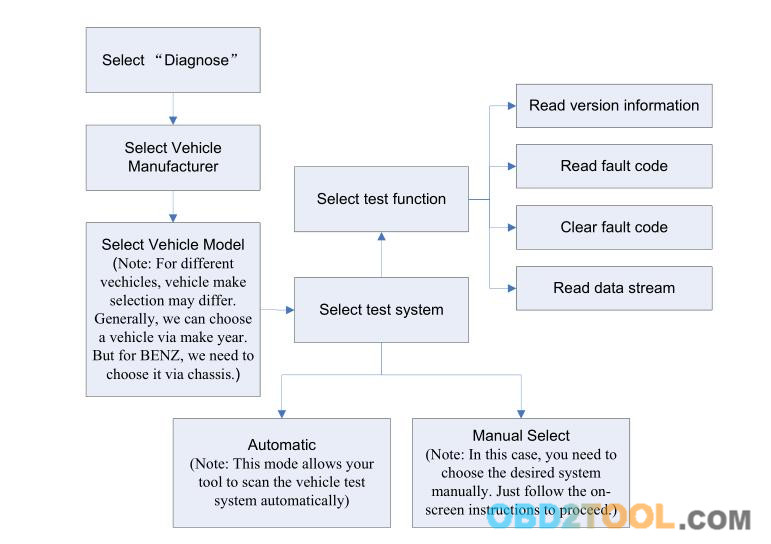

5.2 System Diagnosing

This function is specially designed to diagnose electronic control

system of single vehicle model which includes the following systems:

● ENG (Engine)

● ABS (Anti-lock Brake System)

● TCM (Transmission Control Module)

● SRS (Supplemental Restraint System)

Notes:

● Before diagnosing, please make sure the diagnostic program

corresponding to certain vehicle model has been installed on your CRP12X

Premium.

● For vehicles manufactured by different vendors, it is

possible that it has different diagnostic menus. Refer to the flowchart

illustrated as below to diagnose a vehicle:

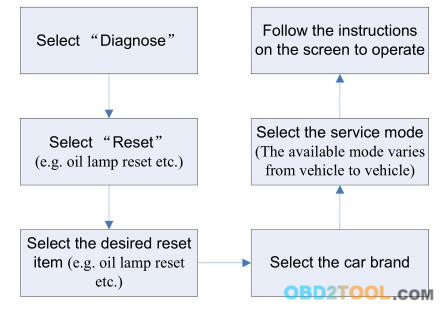

5.3 Resetting (Only applies to CRP129 Premium)

5.3 Resetting (Only applies to CRP129 Premium) In addition to amazing & powerful diagnostic function,

Code Reader Scanner CRP129P

also features Oil / Service lamp reset. There are two methods to reset

service lamp: Manual reset or Auto reset. Auto reset follows the

principle of sending command from CRP129 Premium to vehicle’s ECU to do

resetting. While using manual reset, users just follow the on-screen

instructions to select appropriate execution options, enter correct data

or values, and perform necessary actions, the system will guide you

through the complete performance for various service operations.

Follow the flowchart shown as below to perform resetting.

5.4 Review

5.4 Review This function is used to review or delete the recorded DTC, Data Streams and Freeze Frame.